Let Your Lights Shine

Running Light Maintenance

by Chris Hill, July 2017

I don’t sail in the dark very often, but when I do, it’s usually between July and December. In August through October, warm pleasant evenings suddenly turn dark, and in December it’s nice to get out and look at the Christmas lights. When out in the harbor after sunset, it’s a good idea, and a legal requirement, to have working running lights.

To keep your lights in working order it is a good idea to check and maintain the electrical system from time to time. Every year in late summer, I pull apart the running lights, clean and grease them to improve reliability. So far, I haven’t got stuck in the dark without running lights (knock on wood).

Take the three screws out that hold the running light to the boat, being careful not to drop the screws or the screwdriver into the water. Note that there are several parts to the light. Be sure to hang onto all of them.

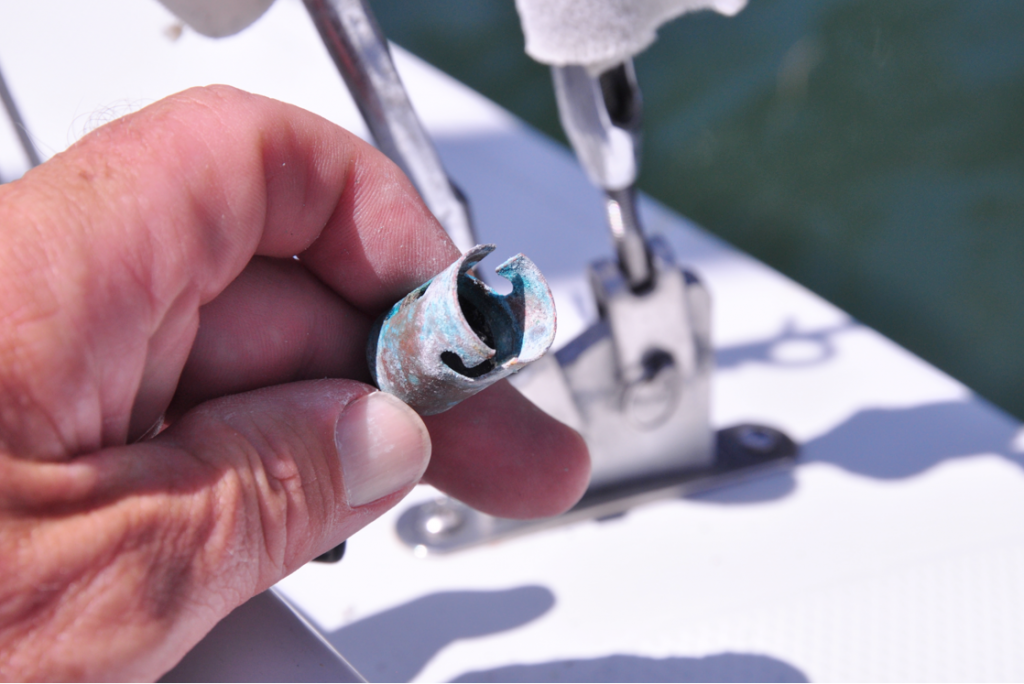

Aha… Corrosion shown here on the contacts on the base of the bulb and on the socket. Moisture plus dissimilar metals in contact with each other and the atmosphere means corrosion will happen. We just need to clean it away, and slow down its future growth.

To clean off the corrosion, I like to use contact cleaner, readily available from an auto parts store (Kragen, Hub) or an electronics store (MarVac, Fry’s) plus a wire brush. (Funny that the can says “Cleans and Protects”, then also on the label it says “Leaves no residue”. Not sure what kind of protection is provided when nothing is left behind… Anyway, it helps to get things thoroughly clean, but I wouldn’t count on any “protection”.)

I also like to use a wire brush for the cleaning operation. This 3 pack of brushes from Home Depot (Paint department) has a stiff nylon brush, a brass brush (good for cleaning steel without scratching it), and a steel brush. It’s ok to scratch the electrical contacs, so use the steel one for this job. I spray on the cleaner then quickly scrub with the wire brush to clean, then use more spray cleaner to get rid of the crud. Be careful that no strands of wire brush remain. The nylon brush is good to make sure nothing meteallic is left behind.

After cleaning, the base should have a copper-ish looking color. Most importantly, the two contacts inside the base

need to be thorougly cleaned. This is a one-filament bulb, and there are two contacts on the base, so the socket itself is not actually part of the circuit, and the base contacts are the most important part.

After cleaning I like to apply dielectric grease, also available at an auto parts store. The dielectric grease keeps moisture and air away from the metal, preventing corrosion, at least as long as it stays on the surface.

Here’s the bulb cleaned, then coated with the grease, ready to be reinstalled. Put it all back together with grease coating the electrical contacts, and your lights should work fine, at least until corrosion catches back up with you.

Great job, Chris! Very clear instructions!

Another alternative is to just save the time and replace with LEDs.

Amazon has a pair of ALLOMN ABS (plastic) LED lights for about $30.